How to Set Print Density on 100x150mm Thermal Labels? A Practical B2B Guide

Share

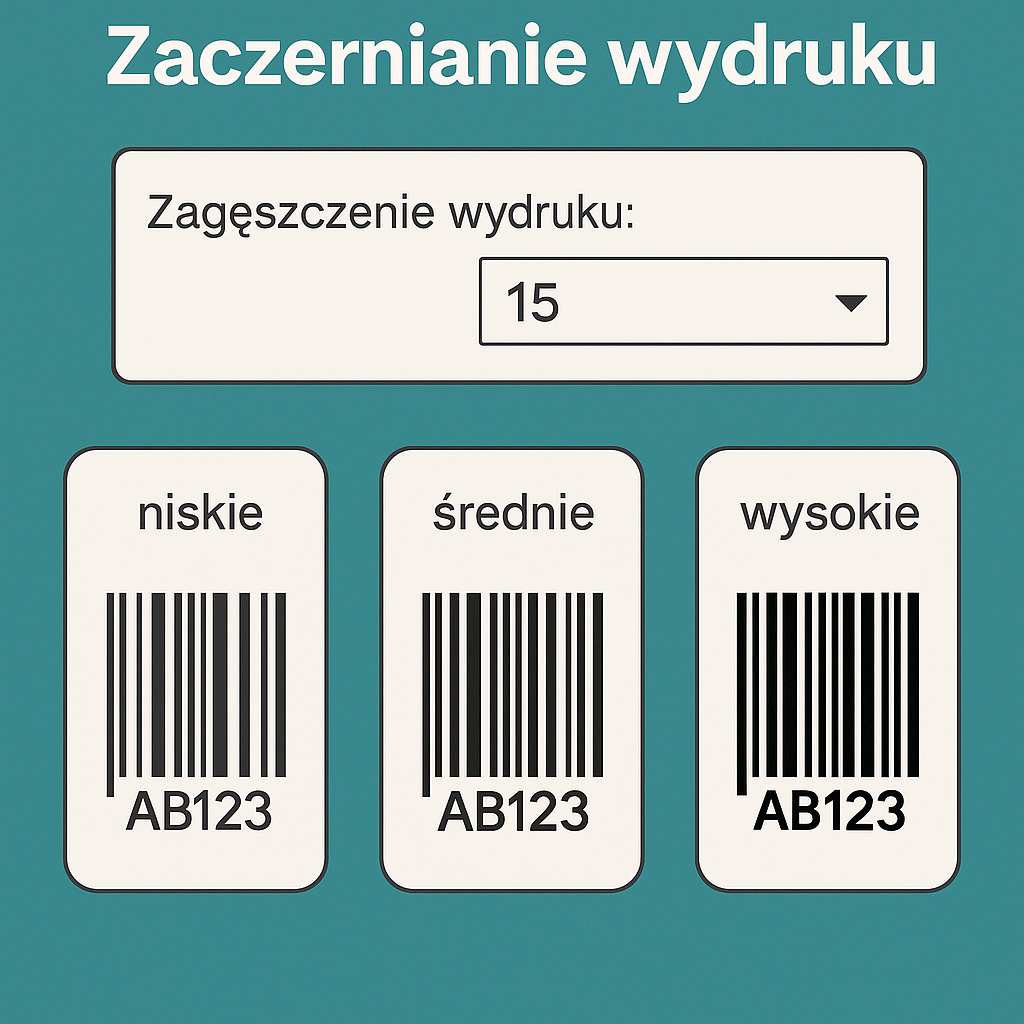

Print blackening – a key function when working with 100x150 mm thermal labels

Thermal labels have become a standard in logistics, e-commerce, and industrial environments. One parameter that often escapes the attention of customers and users of thermal printers is print density , or the level of thermal image transfer density. This effect and setting directly impacts print legibility and durability—key aspects in permanently transferring data to paper.

What is print blackening?

Density control regulates the printhead temperature. The higher the density, the more intense and clear the print on the label. This function allows you to adapt the label's appearance to the conditions of use – from temporary labels to labels used in transport processes, where abrasion resistance and error-free barcode scanning are essential.

Practical example – Zebra GX420d printer

In the Zebra GX420d printer, the density option can be found in the Options tab of the driver settings. The default value is 15 (on a scale of 0–30). For 500 Zebra EKO 100x150 mm white thermal labels, we recommend testing values in the 12–17 range, which ensures optimal contrast and saves on consumables.

View product:

White thermal labels 100x150 mm – 500 pcs. Zebra EKO

Why is it worth paying attention to density and selecting this parameter correctly for your printer?

- Better barcode quality

- Fewer scanning errors

- Less wear on the printer head

- Professional label appearance

- Greater print durability

In the e-commerce industry, where every element of logistics affects process efficiency, details such as print quality can have a real impact on operational reliability and, above all, on the quality of the labels we generate.

Summary

Properly setting the density is a quick way to improve print quality and save money. It's worth remembering this feature when implementing new label rolls or changing paper types. Use our labels and optimize your company's labeling process.